Cashflow Masterclass – The Cash Conversion Cycle

As part of our commitment to improving the financial wellbeing of our clients, we want to educate business owners on the fundamental principles of cashflow management. In this article we deep dive into cashflow cycles and the Cash Conversion Cycle (CCC) – Why it is important, how to measure it and some benchmark examples for different industries. If you get stuck on any terms in here there is a glossary at the bottom of this article, and as always, we are here to help.

Understanding Cashflow Cycles

A cashflow cycle refers to the period it takes for a business to convert its investments in resources, such as inventory and raw materials, into cash flow through sales. It’s a measure of how efficiently a company manages its cash inflows and outflows over time. Understanding cashflow cycles is crucial for managing working capital and ensuring that the business has enough cash on hand to meet its obligations.

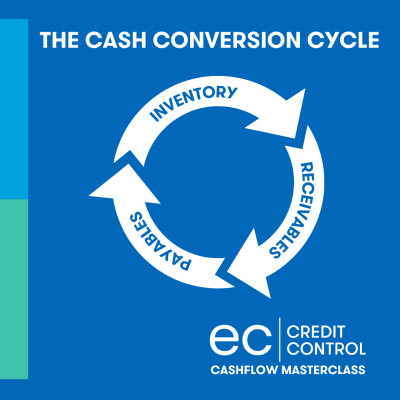

The Cash Conversion Cycle (CCC)

The cash conversion cycle is a metric that reflects the overall efficiency of a company’s cashflow cycle. It combines the inventory period, receivables period, and payables period to determine how long cash is tied up in the production and sales process before it is converted back into cash.

The key components of the cash conversion cycle are:

- Inventory Period:

– This is the time it takes for a business to purchase raw materials or inventory and convert them into finished goods.

– The inventory period starts when the company buys inventory and ends when that inventory is sold.

– For example, if a company buys raw materials on January 1st and converts them into finished goods by January 15th, the inventory period is 15 days.

- Receivables Period:

– The receivables period is the time it takes to collect cash from customers after a sale has been made.

– It begins when the goods or services are sold on credit and ends when the cash is received from the customer.

– This is the part where we come in, we can construct tailor made terms of trade for your business that let you credit check new customers (and potentially avoid serial defaulters) and outline expectations for payment timeframes and consequences for default.

– For example, if a customer buys goods on January 15th and pays the invoice on February 14th, the receivables period is 30 days.

- Payables Period:

– The payables period refers to the time a business takes to pay its suppliers for the goods and services it has purchased.

– This period starts when the inventory is purchased and ends when the payment is made to the supplier.

– For instance, if a company buys materials on January 1st and pays the supplier on January 31st, the payables period is 30 days.

The CCC is calculated using the following formula:

Cash Conversion Cycle (CCC) = Inventory Period + Receivables Period – Payables Period

Positive CCC: Indicates that the company must finance its operations from other sources (like loans) before receiving payment from customers. This happens when the sum of the inventory and receivables periods exceeds the payables period.

Negative CCC: Suggests that the company receives payment from customers before it needs to pay its suppliers, providing a cash flow advantage.

Example of a Cash Conversion Cycle

Let’s consider the cash conversion cycle of a small manufacturing company:

- Inventory Period: The company buys raw materials on January 1st and manufactures finished products by January 21st. The inventory period is 20 days.

- Receivables Period: The company sells the finished products to customers on January 22nd, offering 30-day credit terms. Customers pay their invoices on February 21st. The receivables period is 30 days.

- Payables Period: The company pays its suppliers for the raw materials on February 1st. The payables period is 30 days.

Using the cash conversion cycle formula:

CCC = 20 days (Inventory) + 30 days (Receivables) – 30 days (Payables) = 20 days

This result indicates that the company’s cash is tied up in operations for 20 days before it is converted back into cash.

Importance of Managing Cashflow

Efficient management of cashflow is vital for several reasons:

Liquidity: By optimising cashflow, businesses can ensure they have enough cash on hand to meet daily expenses, such as payroll, rent, and utilities.

Profitability: Reducing the cashflow cycle can decrease the need for external financing, thereby reducing interest costs and increasing profitability.

Operational Efficiency: A shorter cashflow cycle indicates that the business is efficiently converting its investments in inventory and receivables into cash.

Strategies to Improve the Cashflow Cycle

Reduce Inventory Period: Streamline production processes or implement just-in-time (JIT) inventory management to reduce the amount of time inventory is held before being sold.

Shorten Receivables Period: Encourage customers to pay sooner by offering discounts for early payment or tightening credit terms. We can help improve your receivables period, book a meeting with your local Business Support Specialist here.

Extend Payables Period: Negotiate longer payment terms with suppliers to delay cash outflows but be careful not to harm supplier relationships.

Understanding and managing the cashflow cycle helps businesses maintain financial stability, optimise operations, and improve overall financial health.

Typical Cash Conversion Cycles for Various Industries

The typical Cash Conversion Cycle (CCC) varies widely across industries, reflecting the differences in how they manage inventory, receivables, and payables. Here’s an overview of the typical CCC for various industries:

Retail Industry

Typical CCC: 30 to 60 days

Characteristics: Retailers often have short inventory periods due to fast-moving consumer goods, but receivables periods can be moderate if customers pay by credit card or on credit terms. Payables periods can be relatively long, as retailers often negotiate extended terms with suppliers.

Example: Grocery stores usually have a shorter CCC because of the high turnover of perishable goods, whereas electronics retailers may have a longer CCC due to higher inventory costs and longer payment terms.

Manufacturing Industry

Typical CCC: 60 to 120 days

Characteristics: Manufacturing companies often have long inventory periods due to the time it takes to convert raw materials into finished goods. Receivables periods can also be long, especially in B2B settings where customers often have extended payment terms. Payables periods vary depending on supplier relationships.

Example: A car manufacturer may have a CCC on the higher end due to the complexity and time involved in production, coupled with long payment terms from dealerships.

Technology Industry

Typical CCC: 30 to 90 days

Characteristics: Technology companies, particularly those dealing with hardware, can have moderate to long CCCs. Inventory might include high-cost items with longer sales cycles, while receivables can be extended due to large corporate customers. However, software companies may have much shorter CCCs due to digital products that don’t require inventory.

Example: A software company might have a CCC close to zero or even negative if they receive payment upfront for subscription services, whereas a hardware company like a computer manufacturer might have a longer CCC.

Pharmaceutical Industry

Typical CCC: 100 to 150 days

Characteristics: The pharmaceutical industry often has a long CCC due to extensive R&D processes, lengthy regulatory approvals, and significant time spent in the production of drugs. Inventory periods are extended by the need to stockpile drugs, and receivables periods can be long due to the complex payment structures of healthcare providers and insurers.

Example: A major pharmaceutical company might have a high CCC due to the need to maintain large inventories of drugs while waiting for payments from healthcare providers.

Automotive Industry

Typical CCC: 60 to 120 days

Characteristics: The automotive industry typically has a long CCC due to the high value and complexity of inventory (vehicles), lengthy production times, and extended receivables periods from dealerships. Payables periods may be somewhat extended, depending on supplier relationships.

Example: Car manufacturers often have a long CCC because they must hold significant inventories and offer extended payment terms to dealerships.

Food and Beverage Industry

Typical CCC: 20 to 50 days

Characteristics: Companies in this industry often have shorter CCCs due to the perishable nature of their products, which leads to quicker inventory turnover. Receivables periods are generally short, especially in B2C settings, while payables periods can be extended based on supplier agreements.

Example: A fast-food chain might have a very short CCC due to the rapid turnover of food products, while a winery might have a longer CCC due to the aging process of wine.

Construction Industry

Typical CCC: 90 to 180 days

Characteristics: The construction industry often has a long CCC due to lengthy project timelines, significant time invested in inventory (materials and labour), and extended receivables periods as payments are often made in phases or upon project completion.

Example: A large construction firm working on multi-year projects may have a very high CCC due to the time it takes to complete projects and collect payments.

Consumer Goods Industry

Typical CCC: 40 to 80 days

Characteristics: Consumer goods companies typically have moderate CCCs, with inventory periods depending on product type (e.g., fast-moving consumer goods vs. durable goods). Receivables periods are generally moderate, and payables periods can be relatively long due to strong bargaining power with suppliers.

Example: A company that produces household products may have a moderate CCC, as products are sold quickly, but payment terms with large retailers might extend the receivables period.

Apparel Industry

Typical CCC: 60 to 120 days

Characteristics: The apparel industry often has a moderate to long CCC due to the seasonal nature of inventory and the time required for production and distribution. Receivables periods can vary, but payables periods are often extended due to strong relationships with suppliers.

Example: A fashion retailer might have a longer CCC, especially if they need to stock seasonal inventory well in advance and offer credit terms to wholesalers or retail partners.

Summary

The Cash Conversion Cycle is highly industry-specific, reflecting the unique operational and financial characteristics of each sector. Industries with perishable goods or fast-moving inventory tend to have shorter CCCs, while those with complex production processes or extended payment terms often experience longer CCCs. Understanding the typical CCC for an industry helps businesses benchmark their performance and identify opportunities for improving cash flow management. EC Credit Control are experts at cashflow, we can help.

About EC Credit Control

We are a credit management agency that has been supporting Australian businesses for over 30 years. As a specialist in debt resolution and developing business terms and conditions of trade, we have the tools and expertise to help minimise the risk to any business that offers credit. For a free no-obligation consultation, get in touch with your local Business Support Specialist.

Glossary

Cash Conversion Cycle (CCC): A metric that reflects the time it takes for a company to convert its investments in inventory and other resources into cash through sales. The CCC is calculated as the sum of the inventory period and receivables period, minus the payables period.

Inventory Period: The time it takes for a business to purchase or produce inventory and sell it. This period measures how long inventory is held before being converted into sales.

Receivables Period: The time it takes to collect cash from customers after a sale has been made. It begins when the goods or services are sold on credit and ends when the cash is received from the customer.

Payables Period: The time a business takes to pay its suppliers for goods or services purchased. It begins when the inventory is purchased and ends when payment is made to the supplier.

Working Capital: The difference between a company’s current assets (like cash, inventory, and receivables) and its current liabilities (like payables and short-term debt). It represents the liquidity available to a business to meet its short-term obligations.

Liquidity: The ability of a company to meet its short-term financial obligations. Liquidity is typically measured by the amount of cash or easily convertible assets a company has available.

Receivables Management: The process of managing the credit extended to customers and ensuring timely collection of payments. Effective receivables management is critical for maintaining cash flow and reducing the risk of bad debts.

Inventory Management: The process of ordering, storing, and using a company’s inventory. Efficient inventory management helps minimize costs related to excess inventory while ensuring that products are available when needed.

Payables Management: The process of managing a company’s obligations to pay its suppliers. Effective payables management involves negotiating favourable payment terms and ensuring timely payments to maintain good supplier relationships.

Just-in-Time (JIT) Inventory: An inventory management strategy that aims to increase efficiency and decrease waste by receiving goods only as they are needed in the production process, thus reducing inventory costs.

Factoring Receivables: A financial transaction where a business sells its accounts receivable (invoices) to a third party (a factor) at a discount in exchange for immediate cash. This can help improve cash flow but reduces the total amount received.

Equity Financing: The process of raising capital by selling shares of the company to investors. Unlike debt financing, equity financing does not require repayment but dilutes ownership of the company.

Debt Financing: The process of raising capital by borrowing money, typically through loans or issuing bonds. The borrowed amount must be repaid with interest over time.

Working Capital Cycle: The period between the outlay of cash for raw material and the inflow of cash from the sale of finished goods. It includes the inventory period, receivables period, and payables period.

Negative Cash Conversion Cycle (Negative CCC): A situation where a company receives payment from customers before it needs to pay its suppliers, resulting in a cash flow advantage. This is common in industries where customers pay upfront.

Positive Cash Conversion Cycle (Positive CCC): A situation where a company needs to finance its operations from other sources (like loans) before receiving payment from customers. This occurs when the sum of the inventory and receivables periods exceeds the payables period.

Operational Efficiency: The ability of a company to deliver products or services in the most cost-effective manner while maintaining high quality. Operational efficiency helps reduce costs, improve cash flow, and increase profitability.

Seasonal Inventory: Inventory that is held to meet seasonal demand. Companies with seasonal products may experience fluctuations in their cash conversion cycle depending on the time of year.

Supply Chain: The entire process of producing and delivering a product or service, from the procurement of raw materials to the delivery of the final product to the customer. Efficient supply chain management is crucial for optimizing the cash conversion cycle.

Credit Terms: The conditions under which a seller extends credit to a buyer, including the time period allowed for payment and any discounts for early payment. Credit terms directly impact the receivables period in the cash conversion cycle.